Our goal is to keep our finger on the technical pulse and to shape the mobility of tomorrow together with our customers and partners. Efficient. Innovative. Sustainable.

Our technical plastic parts

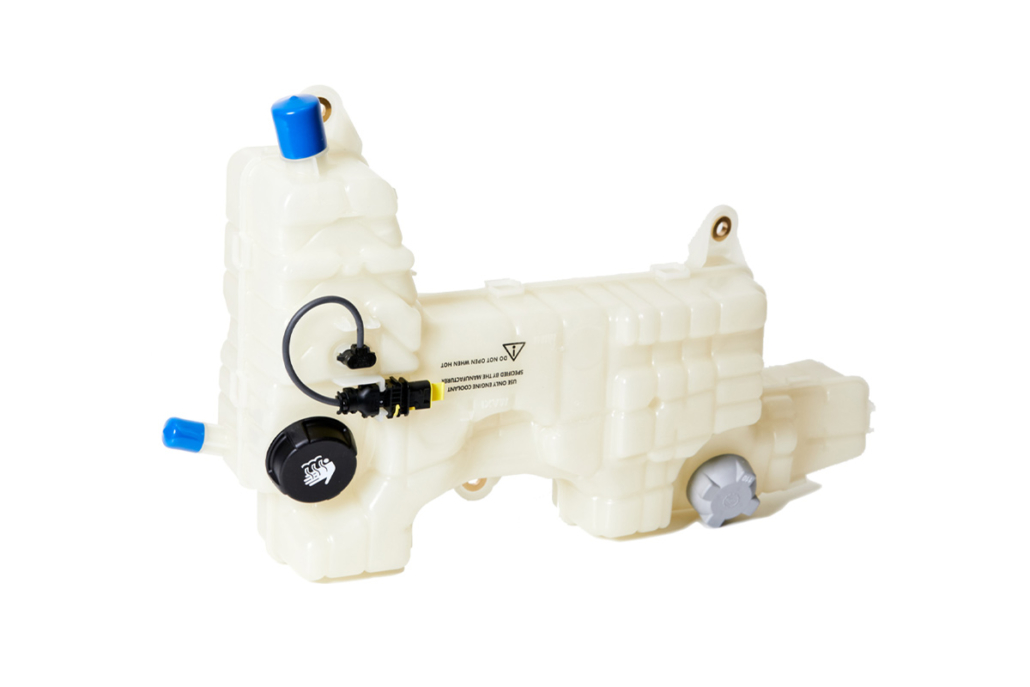

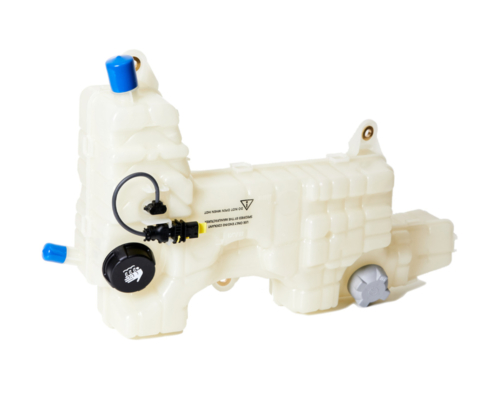

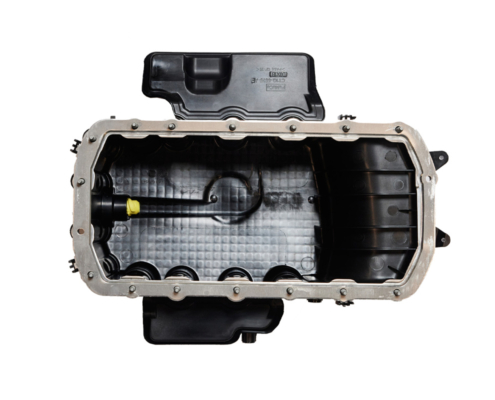

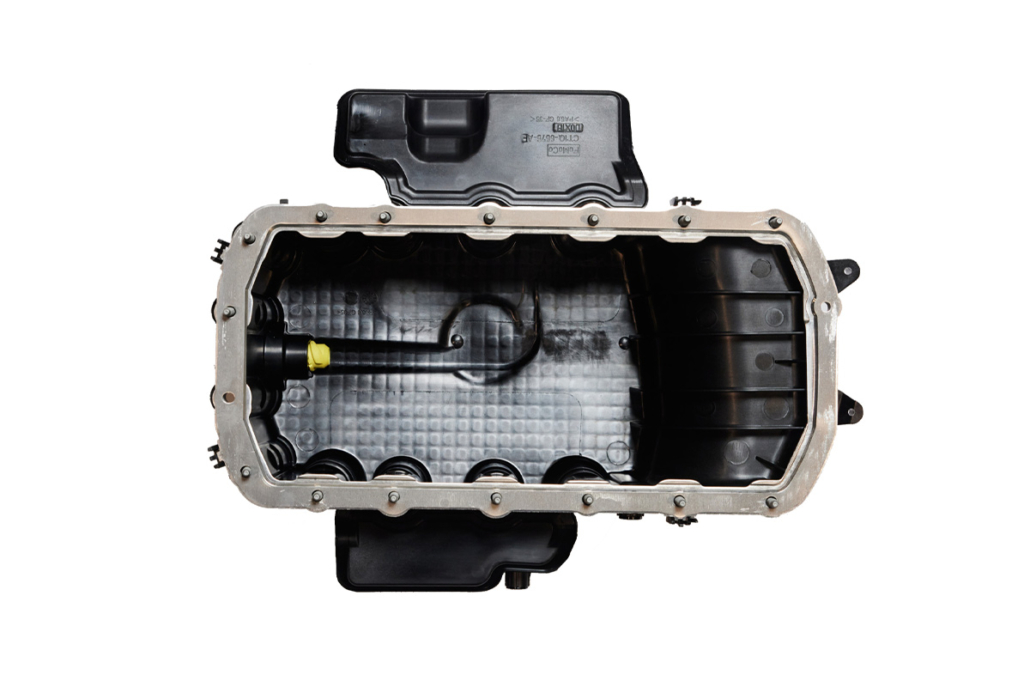

Where aggressive fluids such as coolants, antifreeze or hydraulic oils come into contact with plastics, the highest quality standards are required in tank constructions to ensure safety in the engine compartment.

Thanks to our manufacturing expertise and our growing know-how in polymer processing, MoldTecs supplies highly complex technical plastic parts that can withstand all extreme operating conditions. In combination with our modular manufacturing concept, this results in plastic parts of all dimensions that can be used for small cars to trucks and are suitable for all engine or drive variants.

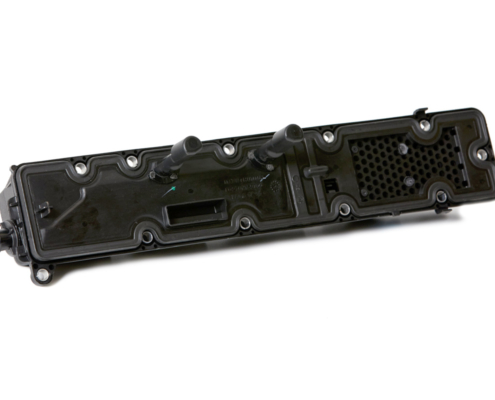

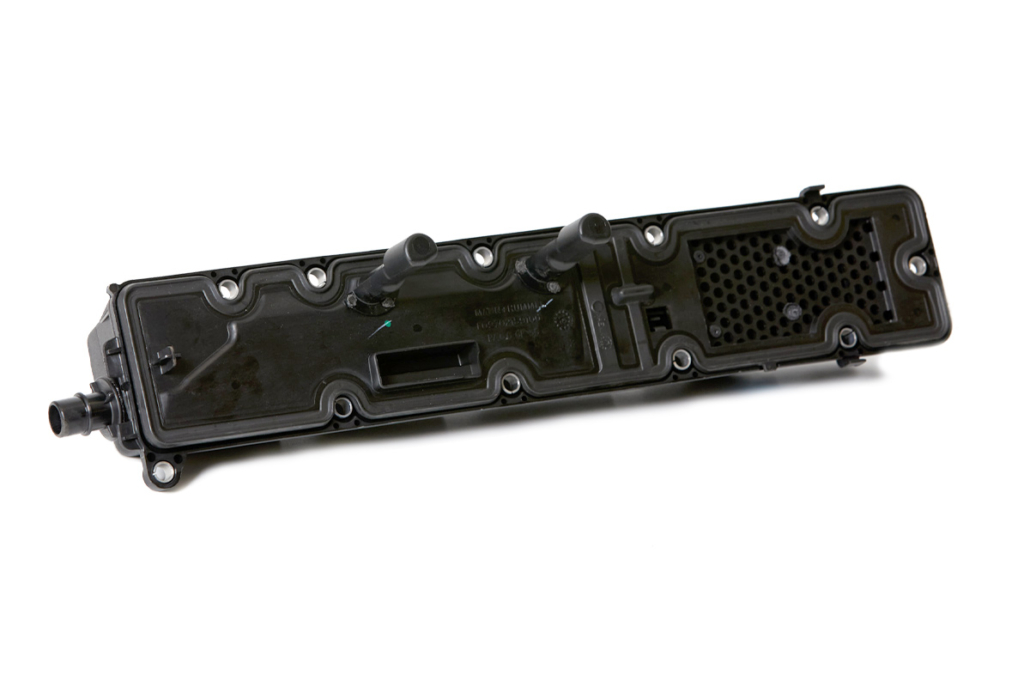

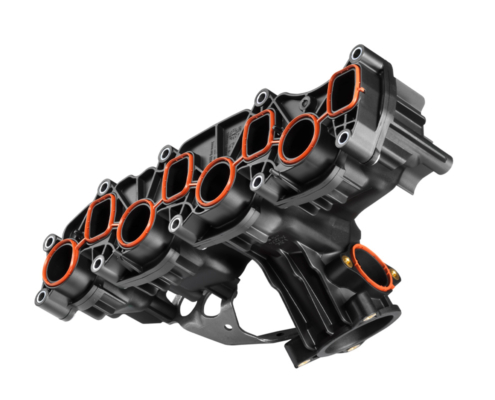

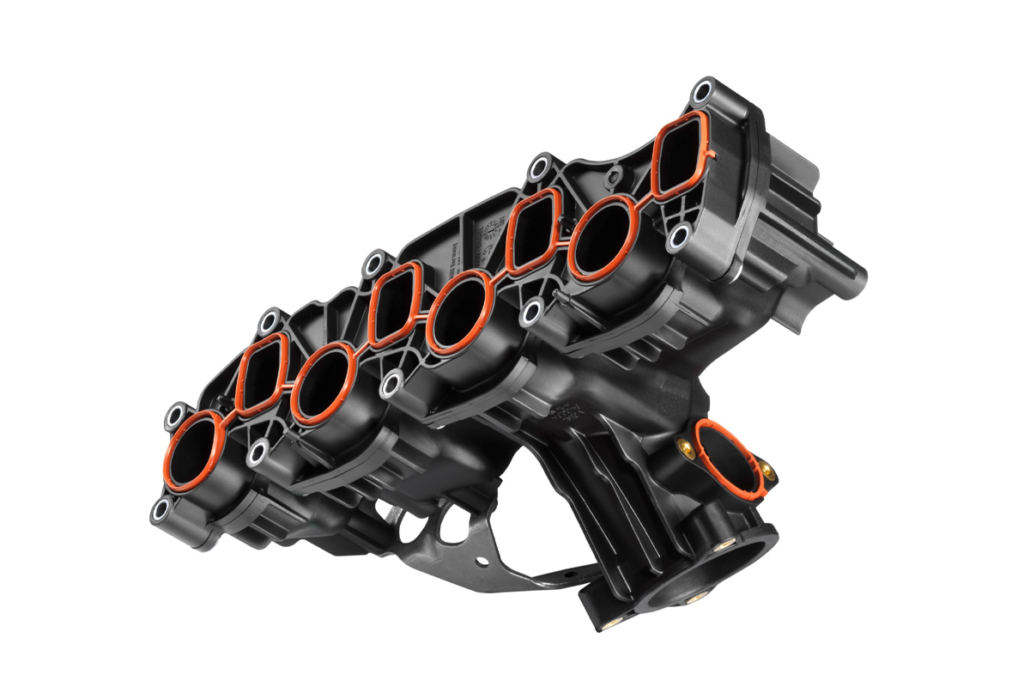

Our intake manifolds

Intake manifolds occupy a key position in the drive system of modern cars. Our expertise in this area ranges from the small 1-liter engine through the 1.6-liter to the V6 variant with 3 liters.

Charge air manifolds are subject to high thermal, mechanical and chemical stresses throughout their service life and are therefore manufactured by us from extremely heat-resistant polymers in several process steps. In this way, we produce the complex components by means of injection molding and blow molding. Depending on the polymer used, the parts are then hot-plate or hot-gas welded, for example. Automated production is completed by manual final assembly and meticulous quality control.

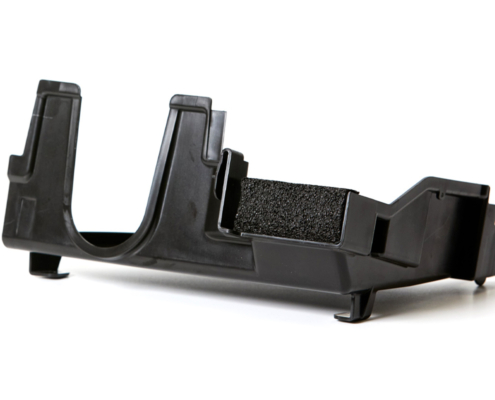

Our charge air ducts

Air ducts in the engine compartment must tolerate extreme thermal, chemical and mechanical stresses and have to function reliably at all times. The greatest challenge in the manufacture of all types of air ducts is to implement the increasingly complex air supply concepts of modern drives in hollow parts, while at the same time conserving materials and resources.

In order to ensure that this efficiency is maintained at the highest level of quality, and thus our customer satisfaction, we offer expertise in the various blow molding technologies.

From conventional blow molding, to 3D manipulation blow molding, to 3D suction blow molding: with us, you can efficiently realize even the most complicated geometries or demanding three-dimensional air ducts.