Perfection on the component starts with the right technology.

Thanks to our technology, your ideas take shape, whatever the complexity of the component or the requirements of the process.

In regard to component geometry, possible openings, inlets or outlets, or a desired surface finish, we realize the specifications together with our customers. Whether injection-molded components, blow-molded hollow bodies or welded joints – trust our dedicated colleagues and rely on first-class technologies.

A true transformation in e-mobility and hydrogen technology succeeds where space for creativity, experience, the pleasure of innovation and the latest technologies meet.

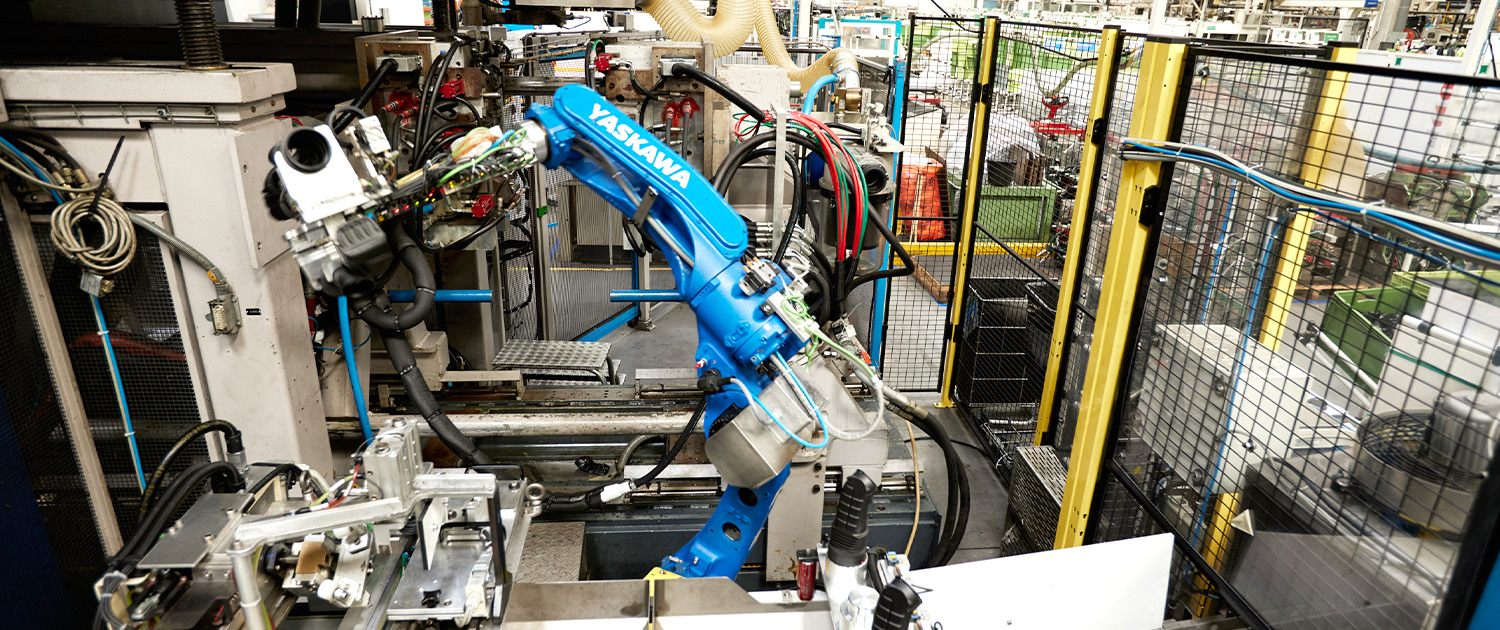

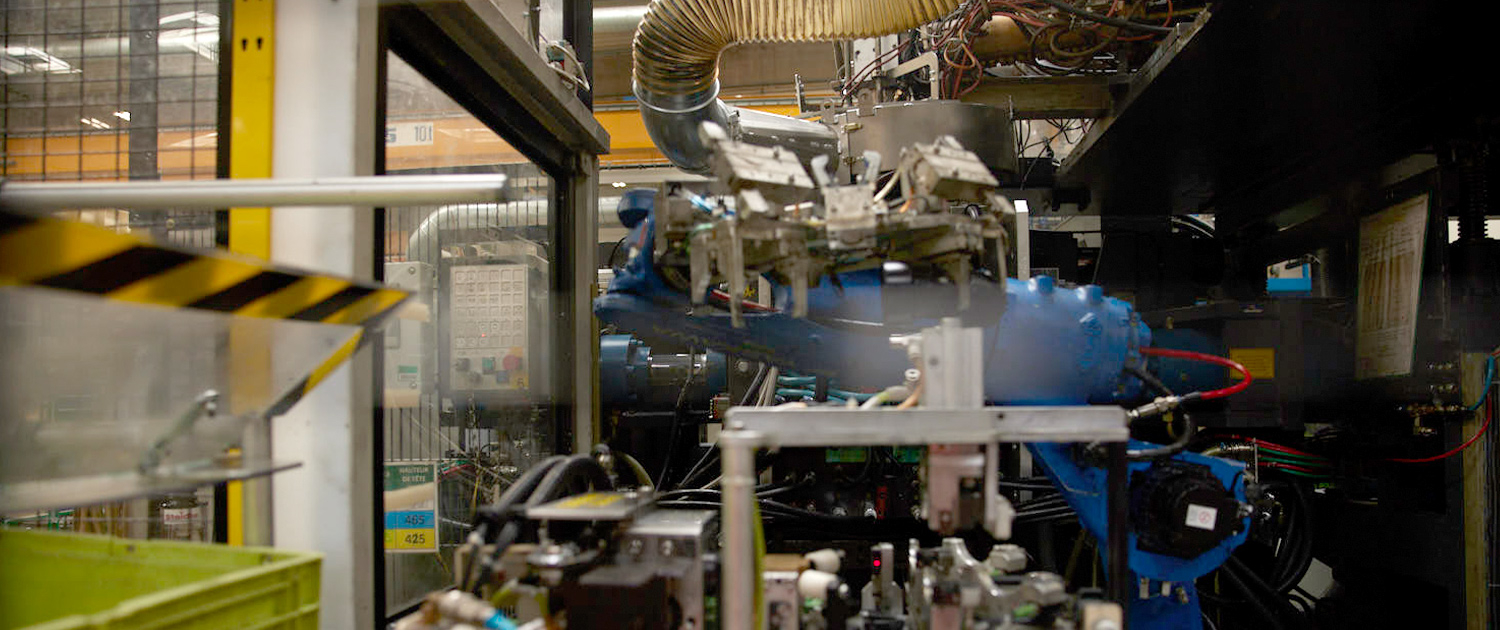

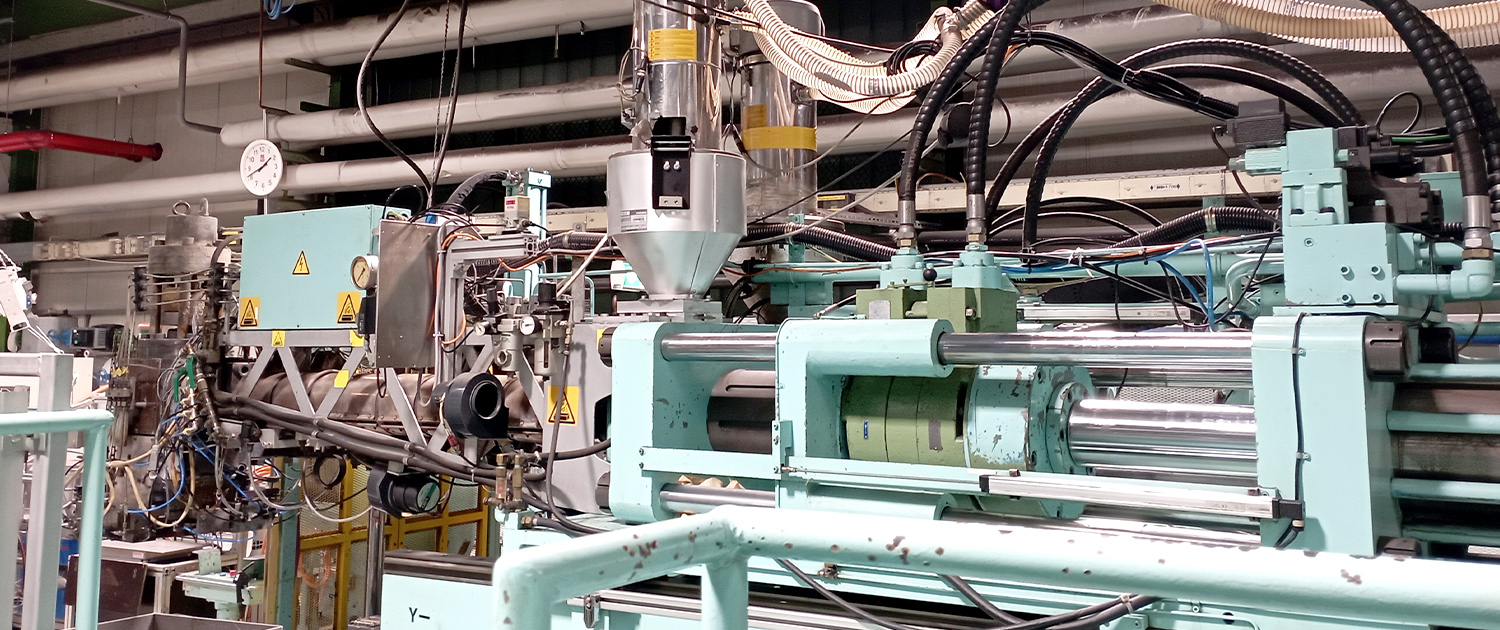

Blow Molding Machines

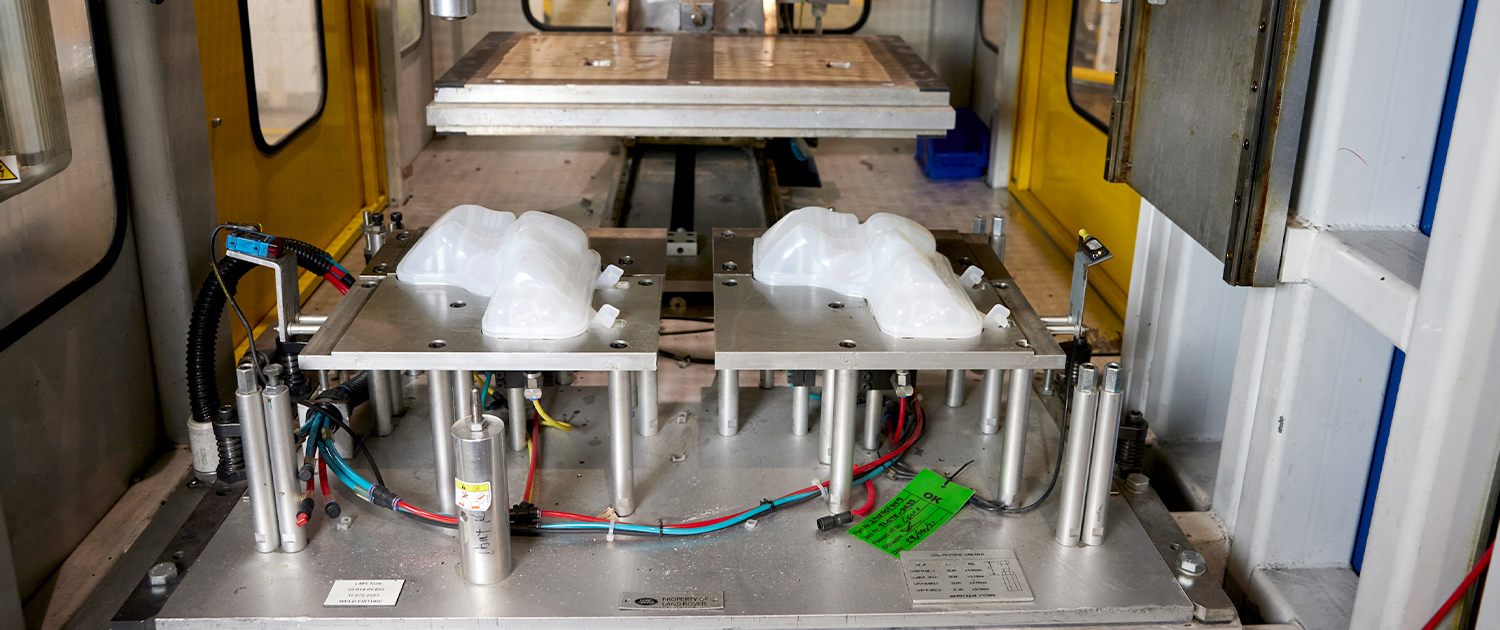

Three things are our focus when manufacturing your blow molded parts: accuracy of fit, durability and resistance. (e.g. against temperatures or chemical influences).

To ensure that our customers can always rely on the same good quality – from batch to batch or throughout different series – we process first-class raw material on 25 state-of-the-art, partly robot-assisted blow molding machines (single or twin). As with our processes, we leave nothing to chance here either.

Traditional 2D blow molding

With our modern and at the same time traditional 2D blow molding machines, we produce high-precision hollow bodies from preforms. The quality we deliver in this process is highly appreciated in the automotive industry.

Bi-material blow molding

Through bi-material blow molding, we manufacture our high-quality hollow parts with multiple high-performance plastics.

Suction blow molding

Using suction blow molding, we produce stretched hollow bodies that meet the highest mechanical requirements.

3D blow molding

We produce complex air ducts and manifolds on innovative 3D blow molding systems. Our processes are characterized by material-saving processing and also guarantee maximum flexibility.

Excell blow molding

Our machines for excell blow molding are characterized by a horizontal mold parting line. This creates processes with which we guarantee a wide range of variants for individual hose sections.

Traditionelles 2D Blasformen

Mehrkomponentenblasformen

Streckblasformen

3D-Blasform-Anlagen

Excell Blasformen

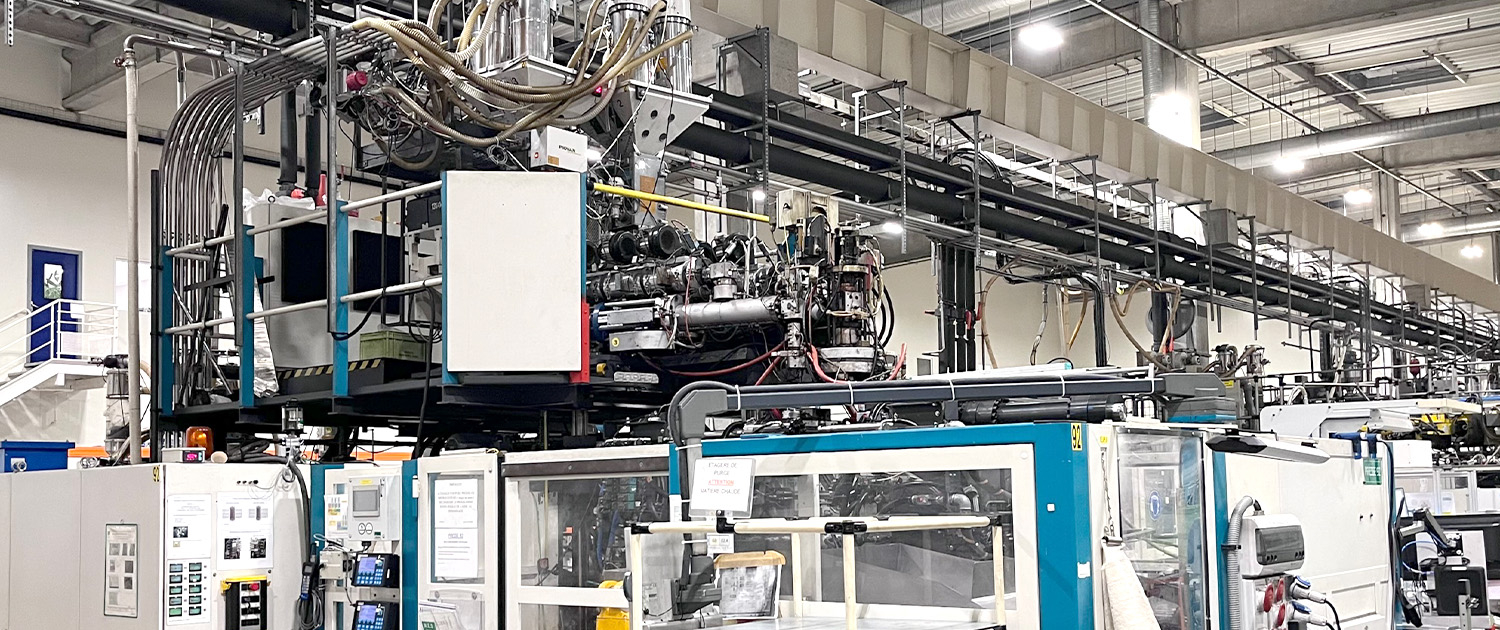

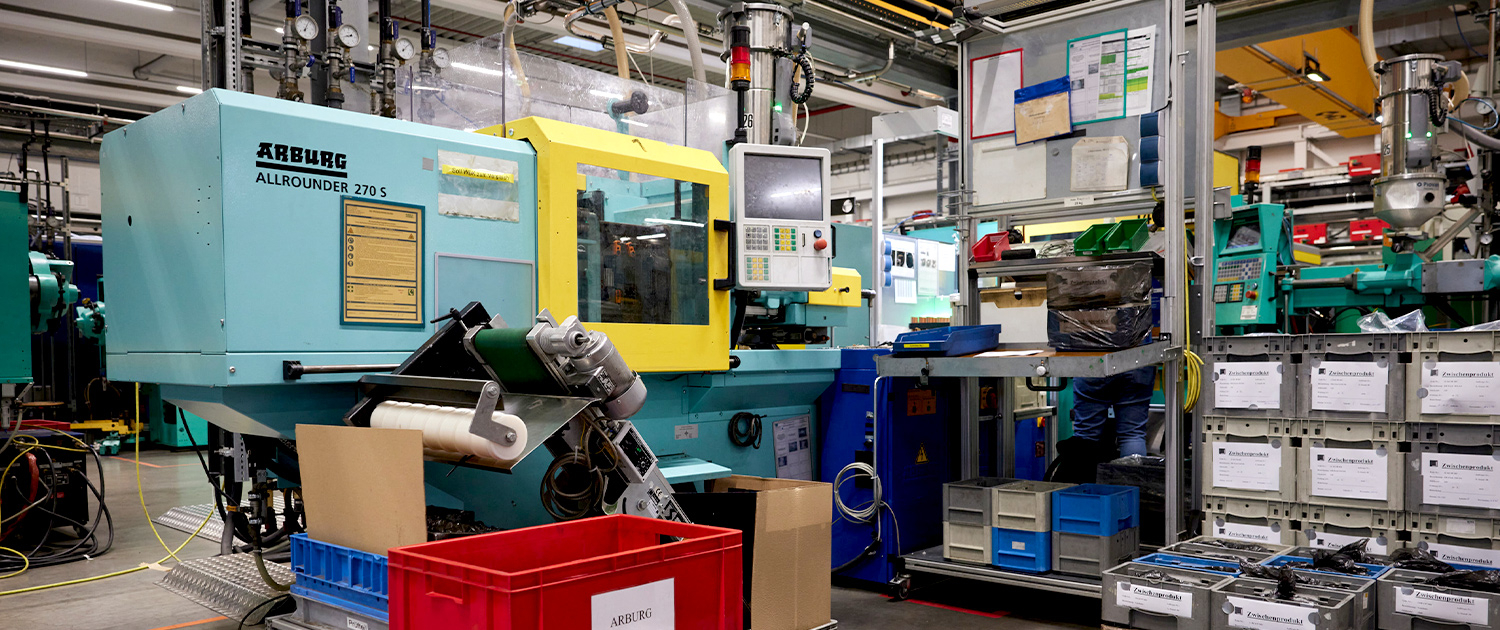

Injection Molding Machines

When it comes to the production of precise parts out of polymers, there is no way around injection molding. Thanks to our many years of experience in this field, we have mastered this manufacturing technology like few others.

Our goal is to produce parts and components for our customers from the best raw materials on the most modern injection molding machines which meet the highest demands. Whether made of polyamide (PA) or polyphenylene sulfide (PPS), for example, customers receive components from us that leave nothing to be desired in terms of design, reliability and mechanical or thermal requirements.

Injection molding (low t)

On our injection molding machines, we are also able to process smaller high-performance plastics into high-quality molded parts on machines with clamping forces starting at 50 tons.

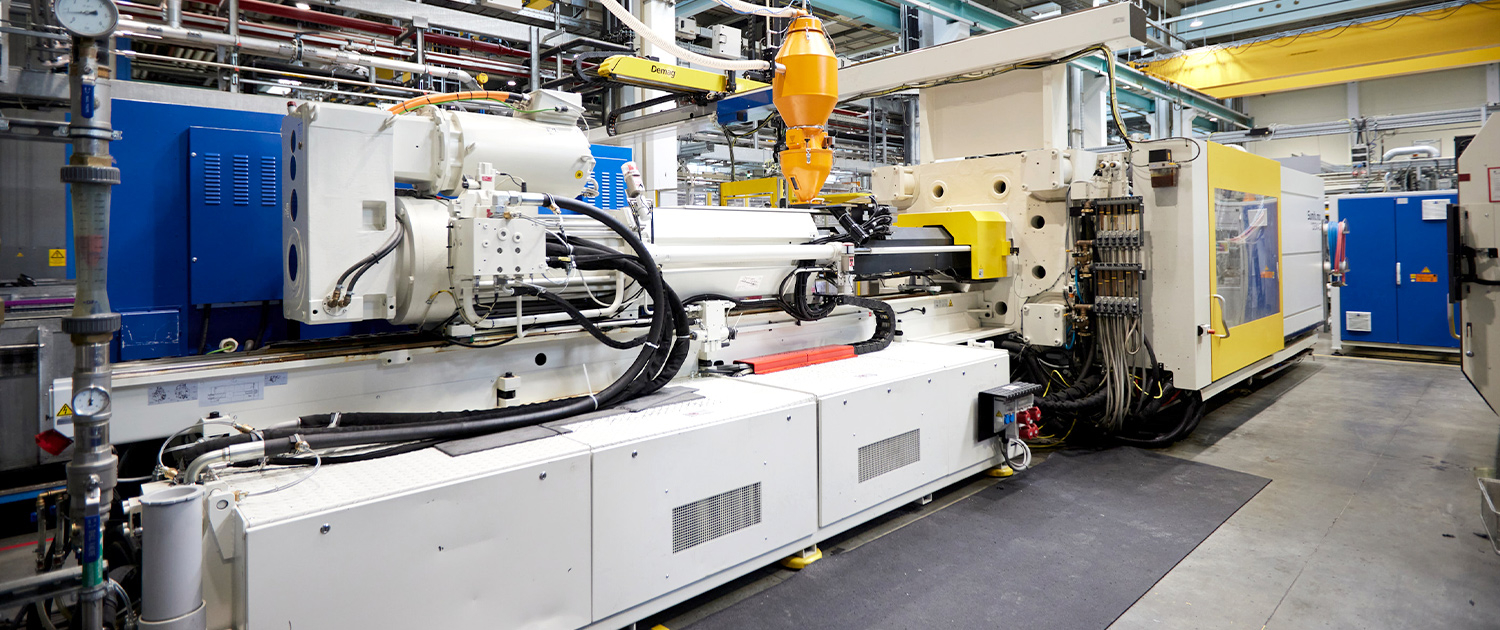

Injection molding (high t)

Clamping forces of up to 1300 tons produce sophisticated molded parts of all sizes out of granules in our state-of-the-art injection molding machines.

bi-material injection molding

In bi-material injection molding, components are molded out of several high-performance plastics that meet the most stringent requirements in terms of quality and quantity.

Spritzgießen (geringe t)

Spritzgießen (hohe t)

Mehrkomponentenspritzgießen

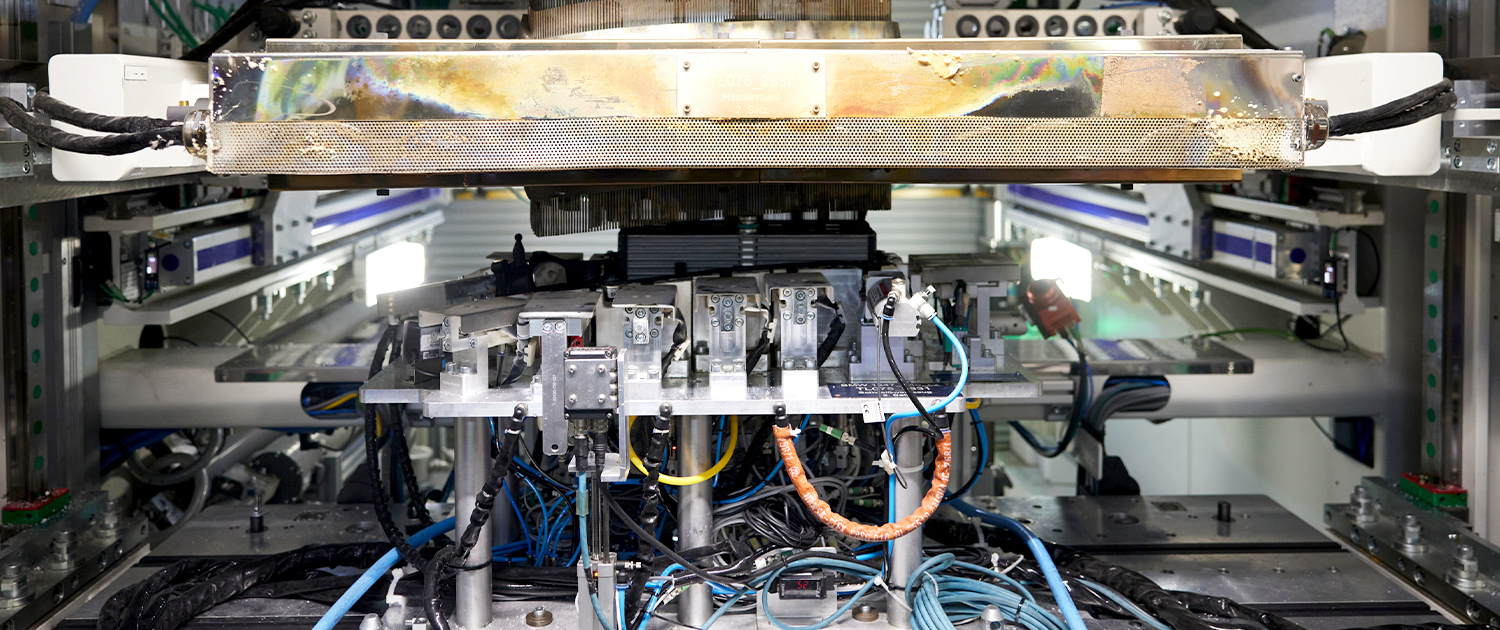

Welding

Strong joints for strong performance. Our excellent welds and high-precision joints withstand even dynamic applications. To ensure that we can guarantee our customers this for each of their products, we specifically use a wide variety of welding processes.

In addition to hot element and ultrasonic welding, we also master processes such as hot gas welding, infrared welding, friction and rotation welding.

However, our selected welding technologies and tools are only one element of our ability to deliver first-class components. Above all, our employees and their mature process know-how guarantee impeccable quality at all times.

Vibration

We use vibration technology to create excellent material-to-material joints between two components. Our customers benefit above all from the high efficiency of this process.

Hot element welding

Hot element welding is one of the most popular technologies. Used for the optimal joining of high-performance plastics, we produce components of excellent quality for a wide range of applications in this way.

Infrared welding

Where infrared welding is used, we join high-quality plastic parts using the latest technology which are later highly appreciated as parts and components, especially by the automotive industry.

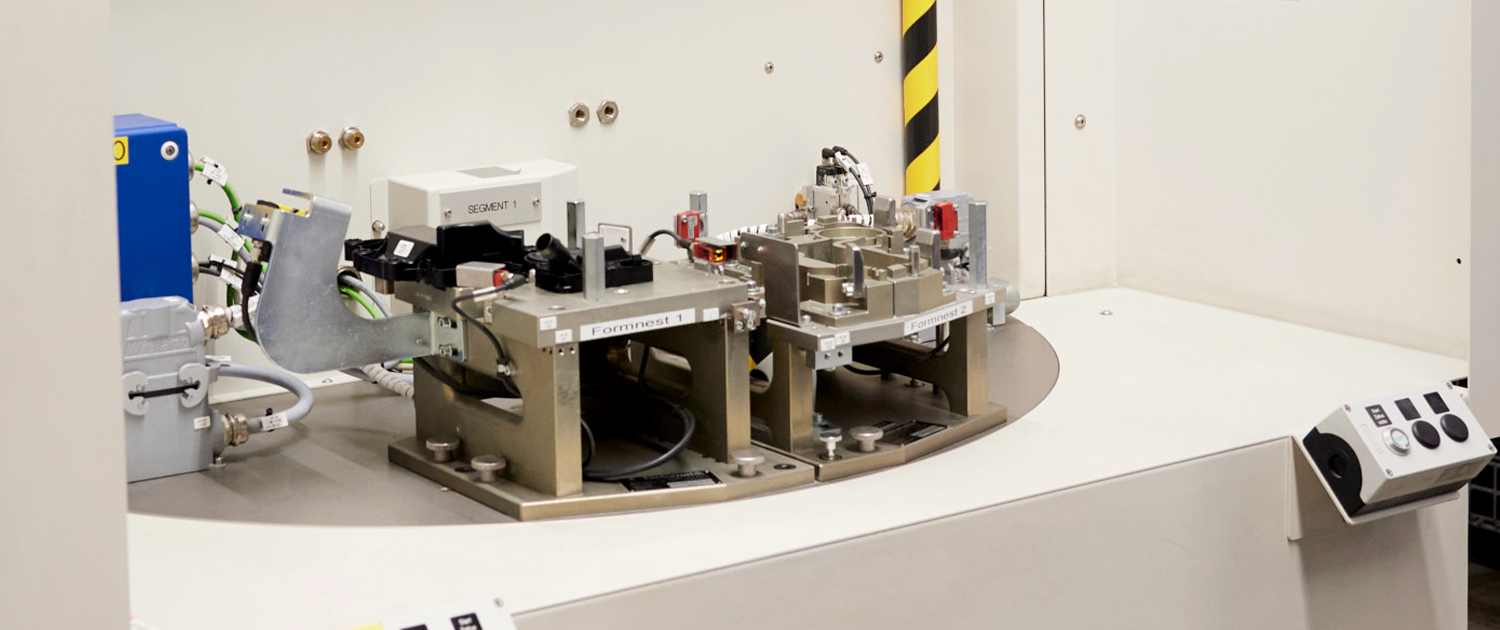

Rotation welding

In rotation welding, we combine different components by means of heat generated during rotation. Our sophisticated processes and high-quality machines not only ensure the best component results, but also efficient production.

Ultrasonic welding

When it comes to joining components quickly and efficiently, ultrasonic welding is the most-recent method of choice. Thanks to modern equipment, we use ultrasound to join high-performance plastics into components that leave nothing to be desired.

Hot gas welding

Whenever components require particle-free and homogeneous welding, hot gas welding is the modern process of the moment. On our equipment, we use hot gas to join polymers into high-strength joints that meet our customers’ requirements.

Laser welding

We use the innovative technology of laser welding to join high-performance plastics. This is how we produce components of the highest quality, especially for the automotive industry.

Reibschweißverfahren

Heiß-Element-Schweißen

Infrarotschweißen

Rotationsschweißen

Ultraschallschweißen

Heißgasschweißen

Laserschweißen

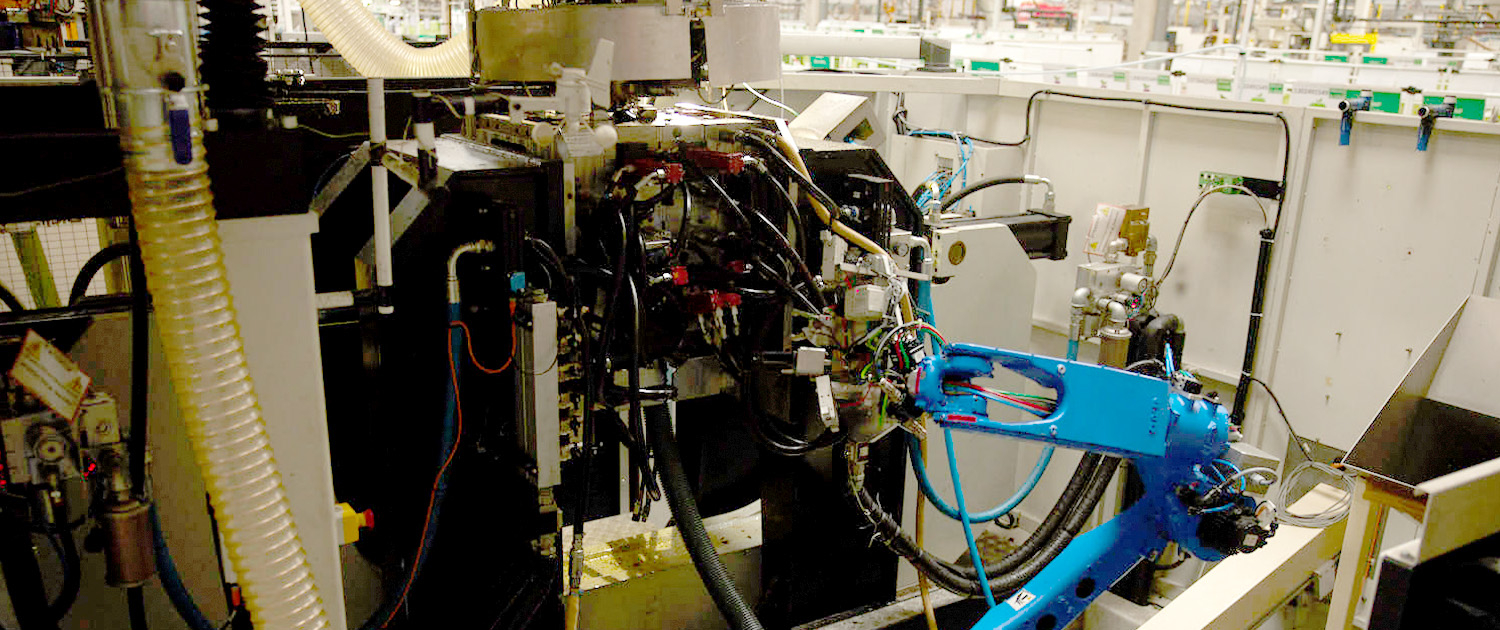

Assembly line & Control processes

Step by step to best quality. Thanks to a high level of vertical integration and interconnectedness, we carry out all joining and assembly work for components and assemblies in our plants using state-of-the-art technology. Whether intake manifolds of various designs, air ducts of different types, tanks, containers or other technical plastic parts. At our modern facilities, experts bring together what belongs together.

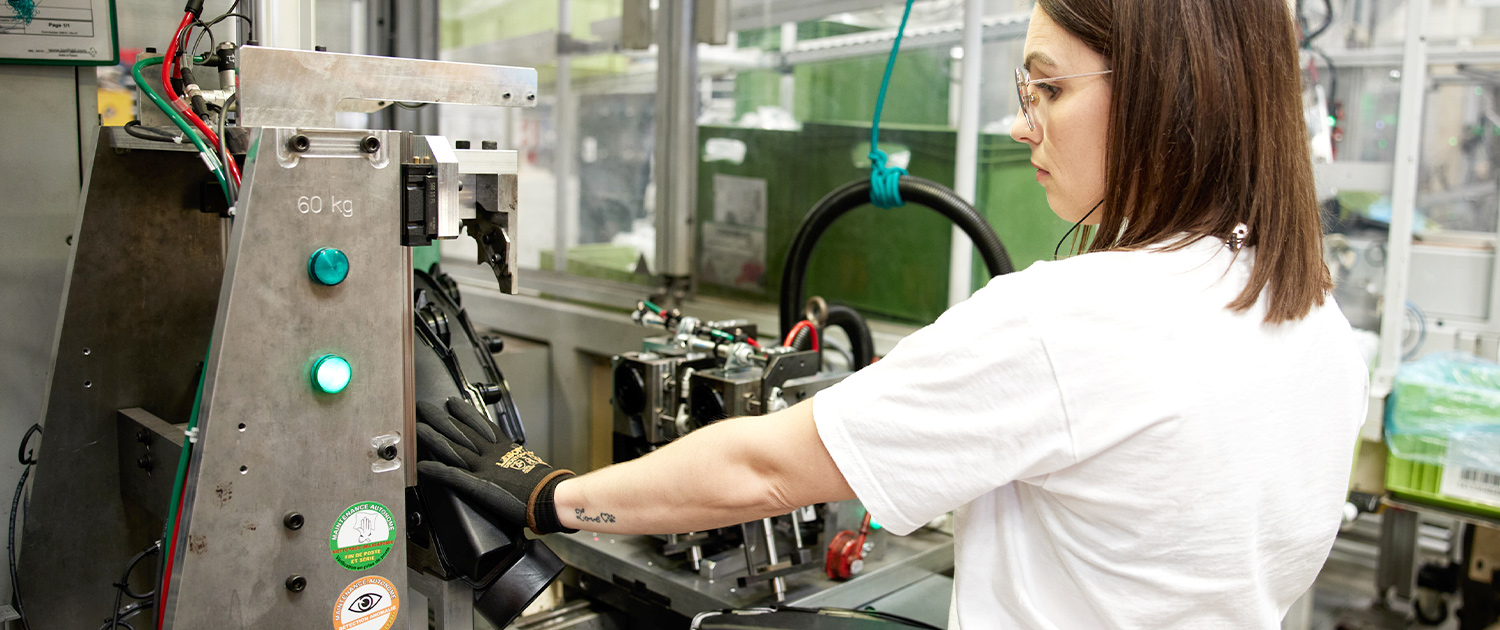

Our assembly is characterized by a high degree of automation and handled by first-class trained specialists. Long-established standardized release processes, worker self-control and fast control loops are the key to consistently outstanding quality. A quality that is regularly tested and confirmed by our engineers and technicians with a wide range of different additional qualifications in quality management.

Modular designed assembly stations

Measurable quality is created where modern automation technology meets modular assembly stations. We ensure the quality of components by optimally dovetailing all process steps.

Crimping

In crimping, we connect individual components on our systems to form parts that are convincing due to their high quality.

Leak testing, calibration, vision control

In order to be able to say “quality first” for each of our components, we carry out the leak tests, calibrations and vision control with the utmost care.

Modular gestaltete Montagestationen

Crimping

Dichtheitsprüfung, Kalibrierung und 100% Kontrollen

The mobility transition needs strong protagonists. As a globally active supplier of plastic components, we meet all challenges: We manufacture and develop solutions for a sustainable future.