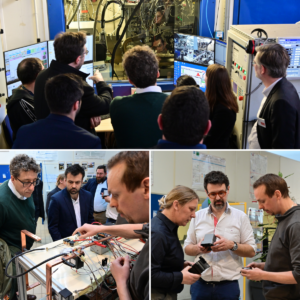

On Friday 15 November, we were delighted to welcome the management and teaching and research staff of Ecole Centrale Nantes (ECN) to celebrate the launch of our bilateral partnership via an Academic Chair.

The engineering activities associated with this Chair began in October. The aim of the partnership, called TETReIS, is to develop innovative thermoplastic parts to optimize thermal losses of vehicles, thereby improving their efficiency and autonomy.

The scope of activity covers electric vehicles as well as hydrogen and alternative fuel vehicles.

The challenges: key thermal management for electric mobility

With the transition to less polluting vehicles, thermal management of electrical and electronic components has become a crucial element in guaranteeing the performance and durability of electric vehicles (EVs). The lithium-ion batteries, at the heart of these vehicles, must operate within specific temperature ranges to avoid the risk of overheating, reduce degradation and maximize efficiency.

One of the main challenges is range, which is directly linked to energy efficiency and therefore to the thermal management of the system.

Fast charging is also a major issue: although increasingly used to enhance the user experience, it generates a significant amount of heat in the batteries, limiting the speed of charge and potentially affecting their lifespan.

This collaboration between MoldTecs engineers and teacher-researchers from Ecole Centrale de Nantes (ECN) will help accelerate the development of new solutions.

« The objective of this work is clear: to propose and define innovative solutions to improve the thermal performance of electric propulsion systems, in order to increase vehicle autonomy while reducing operating costs, » says Stephane Warnery, R&D Director of the MoldTecs group.

« Drawing on its long-standing expertise in energy efficiency and its structuring research partnerships with industrial companies, Centrale Nantes intends to make a decisive contribution to the thermal optimization of electric vehicles. Centrale Nantes professors and researchers will contribute their know-how in modelling and simulating energy systems for more efficient, safer and more sustainable electric vehicles. The technological advances achieved jointly will also enrich the training of our students, » explains Jean-Baptiste Avrillier, Director of Centrale Nantes.

The MoldTecs Group

Based in Laval, MoldTecs is a global supplier of high-performance plastic parts, developing and producing complex systems for the automotive industry, such as air intake manifolds, high-pressure air ducts, fluid reservoirs and thermal management modules, as well as plastic parts for batteries, electric motors and power electronics. MoldTecs supplies all the major OEMs and many equipment manufacturers worldwide.

The company employs 1,400 people, operates in 9 countries and has 5 production sites and 3 R&D centers in France, Germany, China, India, the USA and soon, Mexico.

The Group’s vision is to make tomorrow’s mobility solutions possible through its products and innovations for electric and hydrogen-powered vehicles.

About Centrale Nantes

Founded in 1919, Centrale Nantes is one of France’s top engineering schools (L’Etudiant) and one of the world’s top 300 (Times Higher Education). It graduates engineers, bachelors, master’s and doctoral students on the basis of very high-level scientific and technological developments. It is international in scope, with 43% of its students being international, representing more than 87 nationalities. Agreements have been signed with 178 universities in 48 countries, and two-thirds of students follow a double degree course.

Research and training at Centrale Nantes are organized around 3 major growth and innovation challenges: sustainable development, digital transition and health. With research platforms ranging from digital simulation to experimentation on prototypes up to full size, and an incubator with 20 years’ experience, the school has major tools for innovation and collaboration with the business world. As part of a proactive policy of integrated research between laboratories and industry, Centrale Nantes has 15 industrial chairs and joint laboratories with leading economic players.

🔐 At MoldTecs, we place a very high value on the security of our information and that of our partners. In times of increasing attacks on company networks, cybersecurity and data protection are essential components of our daily work.

🔐 At MoldTecs, we place a very high value on the security of our information and that of our partners. In times of increasing attacks on company networks, cybersecurity and data protection are essential components of our daily work.